Facilities

Where Every Catch Comes with a Trace

GST Group has established a fully-integrated seafood production system, with all our facilities and plants strategically situated in close proximity to each other. This ensures the safety, sustainability, and traceability of all our seafood products.

Broodstock and Marine Farming

Our Broodstock Farm and Marine Cage Farming Facilities are strategically positioned on Pulau Jerejak, Penang, Malaysia, ensuring pristine ocean conditions.

Operated by seasoned professionals, the facility is the foundation of GST Group’s diverse product range, encompassing Red Snapper, Barramundi, Yellowtail, and more. Our experts manage monitoring and fish fry quality, fueling our Group’s dynamic growth.

Hatchery AND Nursery Farm

GST Group’s pioneering hatcheries, located in Juru and Batu Kawan, Penang, are dedicated to producing fish fries from eggs harvested at our established farms. After collecting eggs from the broodstock facilities, they are transported to these hatcheries for transformation into fish fries.

These juvenile fish are then relocated to marine cage farms to complete their growth cycle. The hatchery employs a home-based method infused with advanced technology to harmonise with the local climate and environment.

The tiger prawns of GST Group are harvested from our high-salinity seawater ponds, strategically located within 30 minutes of our processing plant.

Feed Mill

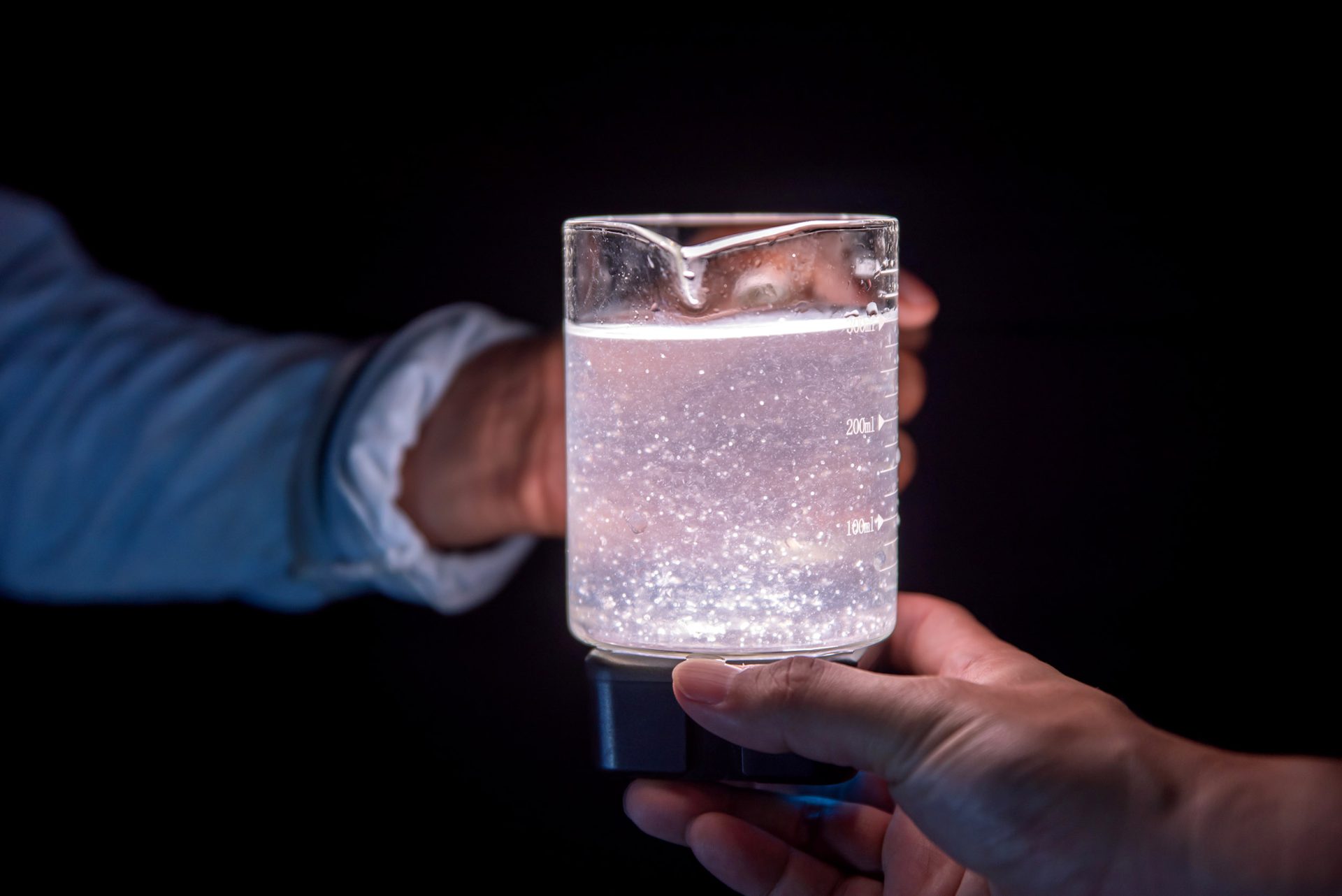

Green Island Feed Mills Sdn Bhd, operational since June 2018, boasts advanced shrimp pelleting and fish extruder production lines with computerised control systems and enclosed pipelines.

Equipped with quality testing equipment and professional technicians, the mill strictly oversees raw material quality and production processes, maintaining a rigorous QC system.

Headquarters and Processing

GST Group’s headquarters and seafood processing plant in the Simpang Ampat Industrial Zone, Penang, is equipped to process up to 4,000 tonnes of top-quality seafood products annually.

The plant handles gutting, filleting, skinning, and trimming, followed by preservation in the freezer. Adhering to international standards such as HALAL, HACCP, BRC and EU certifications, the plant ensures the highest quality products.

We are also Malaysia’s first recipient of BAP certification.

Our advanced production facilities, featuring IQF Tunnel Freezers and Contact Plate Freezers, are specifically designed to preserve the prawns’ unparalleled freshness.

Additionally, our state-of-the-art Prawn Cooker has the capacity to efficiently process up to 2 metric tonnes of prawns per hour, ensuring minimal weight loss and upholding our commitment to the highest quality.